How To

Check and Set Wheel Timing

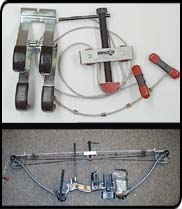

Cam timing is

critically important issue on aggressive two cam bows such as this hatchet cam model from

High Country. (FYI: the camo is Bushlan Brown).

|

|

How To Check and Set Wheel Timing

Use This Step-by-Step

Guide and Your Two-Cam Bow will be Perfectly Timed and Ready to Tune. |

| By Bill Winke |

|

|

|

I spent several hours leaned over the bow, meticulously setting each adjustment. The rest perfectly

centered the arrow, right where it had to be. The nock point was an eighth of an inch

above the center of the plunger, exactly where I like it. The nocks of my arrows were

rotated so that the fletchings would easily clear the shoot-through rest. Everything was

tightened and in place. The bow was ready.

|

|

|

"Fast Flight

harness systems can lengthen from exposure to heat, high levels of moisture, and from

normal stretch associated with breaking-in the bow."

|

|

The shot through paper should have been a formality. The bow was as good

as tuned, I thought. But it wasn't!

Three

hours later I was still scowling at a tear that I had never seen from one of my bows. I

noticed a hammer in the corner; I leered hatefully back toward my bow. No, that would be

too easy. The nock of the arrow was passing through the paper fully 5 inches below the

point. It was shocking! I could have gotten better flight by throwing the arrow. I moved

the nock point more than a half-inch above what I knew was the right position. The arrow

was pointing downward at a disgusting angle. Still the ugly low tear. Then it struck me;

what if the wheel timing is off?

It was off

all right - way off. The bow had felt jerky near the completion of the draw, an obvious

indication of gross mistiming, but I was inexperienced and the symptoms never translated.

Six twists to one of the Fast Flight harnesses brought the bow into perfect time,

subsequently producing a tiny shaft sized hole in the paper. My spirits were instantly

lifted and I placed the hammer back in the corner .

Wheel

timing is the one aspect of bow tuning that even many advanced bow mechanics overlook. It

is the most insidious deterrent to quick success when tuning any two-cam bow. Even

fletching interference, which accounts for most "untunable" bows, is more easily

understood. If you can't seem to get rid of a maddening and persistent vertical tear, this

feature may offer a few answers.

|

| Understanding Cam Timing |

|

A bow may

become mistimed several different ways. We'll look at some of these, but first we need to

understand the root of the synch problem. Dissimilar rollover will always boil down to one

of the harnesses or cables being longer than the other. The lengths of the harnesses

control the position of one wheel relative to the other. Let's look at how this works.

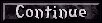

First off,

take note of where your harnesses or cables are attached. One end is solidly grounded to

the axle, whether directly, or through some sort of yoke system. The other end is attached

to the opposite wheel, wrapped partially onto the harness track. When the bow is drawn the

harness is rolled onto the same track which in turn draws the other limb toward it. As

long as both are working together the bow is in time.

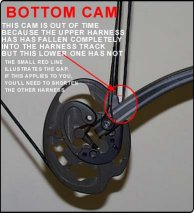

Assume one

harness suddenly stretches a quarter of an inch while the other remains the same length.

The wheel attached to the longer harness has a little freedom to rotate. Now the cams are

in different positions and the bow is out of time. The wheel attached to the longer

harness is "ahead" of the other. When the bow is drawn, this wheel will get to

its full draw position first – thus the term “ahead”. Make sure you

understand that we are talking about the harnesses, not the string. Changes in string

length have no affect on wheel timing.

Fast

Flight harness systems can lengthen from exposure to heat, high levels of moisture, and

from normal stretch associated with breaking-in the bow. Keep your harnesses well waxed to

reduce the stretching caused by moisture. I like to leave my new Fast Flight equipped bows

in a vehicle during a hot day to accelerate heat induced stretching. Get it out the way in

one fell swoop. Once the wax has cooked out and the fibers have stretched, the harnesses

change little when exposed to a lesser degree of heat. They are more or less preset.

A break-in

period is also required . Usually between 200 and 300 shots will set any synthetic,

especially if heat and moisture are also encountered. Allow your bow that many arrows

before assuming it is ready to be tuned for the long haul.

In

the March issue of Edersbow I went into some detail on the characteristics and

applications of several of the modern synthetics. Some offer advantages over Fast Flight

when used on the harnesses. For a more detailed analysis of your options, take a look in

the magazine archives (go back to the Home Page) for the March issue and look up the

article on strings.

|

| How To Check Timing |

|

Before you

can accurately check your timing, you need a precise reference point. You can mark the

wheel with a wax pencil, or the like, to indicate a position relative to the limb at

brace. If the wheel is a hard cam this method may not be accurate enough. The most

accurate reference point I have found is the relationship between each harness and the

groove at the end of its track, with the bow at full draw.

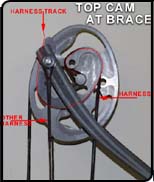

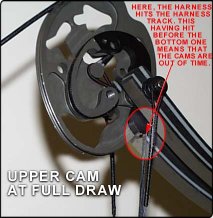

Take

a look at your harness track. Follow the groove all the way around, from the point where

the harness attaches to its end near the axle. This termination – usually a flat

portion of the track - represents the back wall of the draw cycle. Now follow the harness

around the groove as you draw the bow. You'll see the harness drop in next to the axle

right at the end of the draw. The harnesses of both wheels should drop into their grooves

at exactly the same time .

|

| Reset Your Timing |

|

The

harness or cable attached to the wheel that has a headstart as viewed at its braced

position, or reaches the end of draw first (whichever you prefer) must be shortened. Some

bows that were produced in the past had micro-adjustable yoke systems to make timing the

wheels a snap, without having to relax the tension on the bow. Golden Eagle still uses a

similar system, called Xact Timing, which makes it easy to set timing. If your bow is not

so equipped, you will need to twist the longer harness (the one attached to the cam

that’s “ahead”) in the direction of its spiral to shorten it. Steel cables

can be shortened in this manner, as well.

|

|

|

|

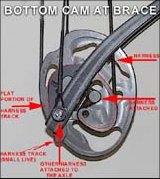

| Using a bow press

remove the tension from the string and harnesses and twist the appropriate harness. Click

photo for bigger image. |

|

photo by rob

eder

|

|

To get at

the end of the harness, where it attaches to the cam, you will need some means by which to

relax the tension of the bow. Most pro shops have bow presses that can be used for this

task. There are also several mini presses available to do the same job. They are my choice

for convenience, and the best I’ve used so far is the Bowmaster.

Simply

remove the harness from its attachment point on the wheel that is "ahead" and

give it a couple of twists to shorten it before replacing. Check the timing again. Repeat

the procedure until the wheels are precisely timed .

Timing

affects arrow flight in a very dramatic fashion – causing tail-high or tail-low tears

through paper. Never assume that your timing is acceptable without checking it often,

especially if you own an aggressive two-cam bow. If wheel synch should change even

slightly during the hunting season your accuracy with broadhead arrows will be destroyed.

One of the final steps in becoming proficient with the mechanical aspects of your

equipment is to understand, monitor, and correct your wheel timing.

Top Page

Return to main Index